An induced draft fan (ID fan) is engineered to maintain a negative pressure in the furnace by sucking the products of combustion from it with slight positive pressure at the discharge end from the bottom of the chimney/stack.

We manage the entire design and construction process

Enoch’s Industries Pvt. Ltd. is a prominent and well renowned Induced Fan manufacturer, supplier in the industry of ventilation centrifugal fans.

Our highly skilled and experienced professionals manufacture premium quality of fans which provides maximum efficiency and minimum maintenance. Our fan impeller is balanced statically as well as dynamically under the IS standard 4894. Meeting customer’s requirements and their satisfaction is our highest priority, hence our development team uses advanced and latest CNC and bending machines to manufacture quality induced fans and the testing team tests every manufactured product before the product goes out from the factory.

Special Features Of Induced Draft Fan

- High efficient & low maintenance

- Low noise level

- Low pressure consumption.

Key Features of Induced Draft Fan

- Excellent Efficiency

- Low Maintenance

- Wear Resistance

- Economic Design

- Cost-Effective

- Low power Consumption

- Low noise level

- Highly Durable

- Customized Size Available

Applications of Induced Draft Fan

- STEEL

- CEMENT

- SPONGE IRON

- POWER

- CHEMICAL

- PHARMA

- MINING

- SEED

- TEXTILE

- PULP and PAPER.

- OIL and PETROLIUM.

- SUGAR

- WASTE MANAGEMENT.

- FERTILIZER

- GLASS and CERAMIC INDUSTRY ETC.

- CEMENT:

- Raw Mill Fan.

- Preheater Fan.

- Coal Mill Fan.

- Cement Mill Fan.

- Raw mill bag house fan.

- Clinker Cooler ESP Fan.

- Cooler fan.

- Bag filter fan.

-

-

- POWER:

- Seal air fans with self cleaning filters.

- Flue Gas Desulphuriation Fans.

-

- Aeration Fans.

- FERTILIZERS & CHEMICALS:

- Flue Gas blower for co2 recovery plant.

- Dryer Fan.

- Fumes Fan.

- Ammonia Reformer fans.

- Fans for DAP/ NPK plant.

- Gas recirculation fan.

- Exhaust Fan.

- Combustion Air Fan.

-

- STEEL & METALS:

- Fans for sinter plant.

- Exhaust Gas Fan.

- Fans for blast furnace.

- Fans for pellet plant.

- Fans for copper & Aluminium smelter.

- Scrubber id Fan.

-

- V) OIL & GAS, PETROCHEMICAL INDUSTRIES:

- Treatment Systems.

- Pressurisation Systems.

- Refining Systems.

- Process Cooling.

- Treatment of exhaust fumes and production emissions.

- Drying and dehydration of residues.

- Explosion proof for Hazardous area.

-

- VI) VENTILATION FANS FOR SHOPPING MALL & THEATER ETC.

-

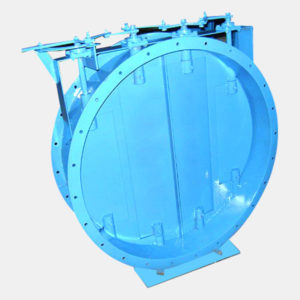

TYPE OF FANS

- Induced Draft Fan.

- Forced Draft Fan.

- Primary Air Fan.

- Secondary Air Fan.

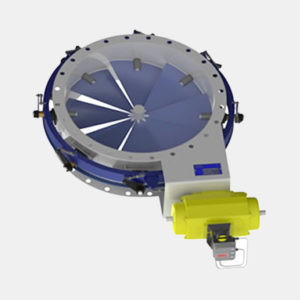

TYPE OF IMPELLER

- Backward inclined.

- Backward Curve.

- Radial Tip.

- Forward Curved Blade.

- Multi Stage Blade & etc.

MATERIAL OF CONSTRUCTION OF FANS

- Stainless Steel fans.

- Carbon Steel Fans.

- PP & FRP.

SPECIAL APPLICATION

- Hot gas circulation fans (up to 500’ C)

- Gas tight fans.

- Explosion- proof fans etc.

- Dual driven fans (e.g. steam turbine-driven fans)

MANUFACTURING FACILITIES

We believe in strict adherence to ISO 9001-2015 quality standards. Were each operation of the Design & Manufacturing process adherence to ISO 9001-2015 quality standards .The final product is bound to be fully in line with Standard quality requirements. Enoch’s Industries Pvt. Ltd. has In-house Design and Development Team .All the fans are tailor made for specific application by Our Design Team using latest CAD software (solidworks ,Unigraphics) to generates 3D modals & drawings. Finite element analysis of all the major components is done in the engineering stage to ensure better & reliable product is delivered to customer.Enoch’s Industries Pvt. Ltd. has a new state of the art 5000 sq.mtr world class manufacturing facility consisting of latest CNC Cutting, Bending , Rolling Machines, Advanced Welding equipment’s/Machines .We have In-house well equipped Paint shop & Machine shop. The workshop currently employs around 50-75 people. All our Employs are trained in using best manufacturing/Assembly process.At Enoch’s Industries Pvt. Ltd. dedicated Quality team, equipped with latest measuring equipment’s ensures that final product is delivered meeting highest quality standards to Customers.

ASSEMBLY AND TESTING

All the fans are fully assembled at our factories. The mechanical run test and performance tests will be conducted as per international standards like API, DIN,JIS,ISO etc.

AFTER SALES SERVICES:

-

-

- Commissioning / Assembly and installation.

- Performance Check.

- Maintenance & Field Services

- Repair

- Case Study.

- Optimization / Retrofit.

-

INDUSTRIAL FAN TYPE:

| Air Flow Range | 500 to 4,00,000 m3/hr |

| Static Pressure Range | 300 to 4,100 PA. |

| Operating Temperature | 20 to 450 ℃ |

| Impeller Type | Backward Curved, Backward Inclined |

| DriveType | Direct/ Belt/ Coupling drive |

| Mounting Type | Base mounted |

| Material Of Construction | Stainless Steel, Carbon Steel, PP & FRP. |

| Air Flow Range | 1,000 to 3,50,000 m3/hr |

| Total Pressure Range | 480 to 10,900 PA |

| Operating Temperature | 20 to 450 ℃ |

| Impeller Type | Backward Curved, Backward Inclined, Radial |

| DriveType | Direct/ Belt/ Direct Coupled |

| Installation Method | Base Mount |

| Material Of Construction | Stainless Steel, Carbon Steel, PP & FRP. |

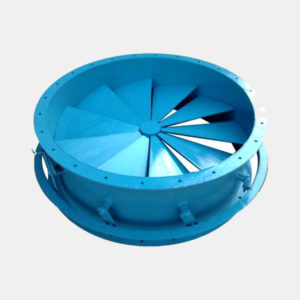

| Air Flow Range | 500 to 1,25,000 m3/hr |

| Total Pressure Range | 1,000 to 19,012 PA |

| Operating Temperature | 20 to 450 ℃ |

| Installation Methods | Base Mounted |

| Drive Configurations | Direct/ Belt/ Axial |

| Impeller Type | Backward Curved, Backward Inclined, Radial. |

| Material Of Construction | Stainless Steel, Carbon Steel, PP & FRP. |

ACCESSORIES:

Our Presence

With an abundance of experience in this industry, we have a reach ion various cities and states of India. We are recognized and demanded supplier in various cities such as Kolkata, Lucknow, Bhilai, Indore, Mumbai, Nasik, Pune, Akola, Jalandhar, Ranchi, Durgapur, Jaipur, and Akola, Raigarh, Jamshedpur, and many more national cities. Our Axial Flow Fans are engineered with high-end raw material which gives excellent results and is high in demand due to its unique integrated attributes. Our highly skilled team of experts makes sure to test every product before making the final delivery to clients. We test our industrial fans with advanced tools to check the performance under the supervision of the testing team.

Moreover, the tools used for testing are Manometer, Temperature sensors, RPM Meters & others. Established in 2007 till today we have expanded our team and industry on a very good note with a new learning and experience every day. We are a reputed brand in the industry and a proud exporter. We also serve our service at an international level which includes Dubai, Indonesia, South Africa, Singapore, Bangladesh, Kuwait, Srilanka, UK, and Australia. Further, we always prefer the satisfaction of customers more than anything else; therefore, we provide customized services to our customers to meet their desired requirements and specifications in a very effective manner.