Pulse Jet Filter consists of filtration elements for providing clean air.Enoch’s Industries Pvt. Ltd. is a reputed Pulse Jet bag Filter manufacturer in Hyderabad.

Our manufactured Pulse Jet Bag Filters are the most demanded pollution control equipment in the industry among our vendors and customers.

We manage the entire design and construction process

Enoch’soffers its product & service with a commitment to continue to solve industrial air pollution problems. Our business expertise covers heating, cooling, waste heat recovery, captive power, water treatment & recycling, air pollution control, waste management & performance chemical. We are engaged in providing durable PULSE JET BAG FILTER that may be designed in pulse jet air systems. The product range on offer today covers pulse jet bag filters supported on-line & off-line type units.Enoch’ssystems are designed to achieve the highest performance with online reliability, minimum of downtime, minimum expenditure and lowest maintenance of the equipment. It ranges highly appreciated for better collection or efficient filtration. We provide economic design, affordable & competitive price for our customer.

Check Out Key Features

- Easy To Install

- Modular Design Available

- Customization Available

- Different verities of filter available

Typical Applications Of Pulse Jet Bag Filter

a) PHARMA.

b) IRON/STEEL.

c) TEXTILE.

d) CERAMIC.

e) PESTISIDES.

f) FOOD.

g) PLASTICS.

h) COAL.

i) RUBBER.

j) CEMENT.

k) FUNDRY.

l) CHEMICAL.

m) FLY ASH.

n) MACHINING.

o) GRINDING.

p) WELDING.

q) FURNACES.

r) COTTON/GINING.

s) WOOD WORKING.

t) LAMINATES.

u) PLYWOOD MFG.

v) GLASS MFG.

w) LASER CUTTING.

x) PLASMA CUTTING.

y) DETERGENT.

Special Features of Pulse Jet Bag Filters

- Low investment and maintenance cost and low assembly work

- Low power consumption combined with high filtration efficiency

- Good accessibility of compressed air supply system

- Simple filter bag replacment

- Simple filter bag replacment

- Compact construction and therefore modest floor space requirement

- Standard design pressure: 500 mm WG

- Design for up to 1000 mm WG

- Unique design with combination of COMPRESSED AIR JET and REVERSE AIRFLOW cleaning

- Effective cleaning of longer filter bags

- Fully automatic bag cleaning mechanism.

OUR PRODUCT RANGE

- Capacity : 500 to 2,500,000 m3/ Hr.

- Guaranteed Out let Emission: 5 mg/Nm3.

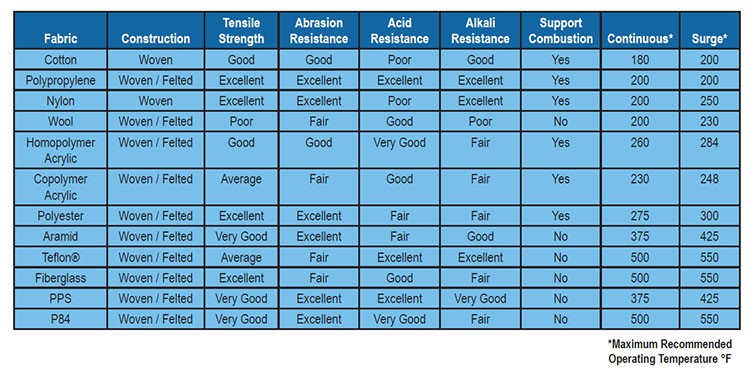

Type of Bag Fabric

TYPE OF Bag

TYPE OF Mounting

- Regular Hopper Entry.

- Flush Mounted Insertable.

- Flush Mounted Circular.

- Casing Entry.

- Circular Tangential entry.

- Pre- separator extended hopper.

- Pre- separator casing with baffle- TKB series.

Typical Bag Fixing

a) Snap.

b) Color.

MANUFACTURING FACILITIES

We believe in strict adherence to ISO 9001-2015 quality standards. We are each operation of the Design & Manufacturing process adherence to ISO 9001-2015 quality standards .The final product is bound to be fully in line with Standard quality requirements. EEssar Enoch’s Industries Pvt. Ltd.. has In-house Design and Development Team .All the fans are tailor made for specific application by Our Design Team using latest CAD software (solidworks ,Unigraphics) to generates 3D modals & drawings. Finite element analysis of all the major components is done in the engineering stage to ensure better & reliable product is delivered to customer. EEssar Enoch’s Industries Pvt. Ltd.. has a new state of the art 5000 sq.mtr world class manufacturing facility consisting of latest CNC Cutting, Bending , Rolling Machines, Advanced Welding equipment’s/Machines .We have In-house well equipped Paint shop & Machine shop. The workshop currently employs around 50-75 people. All our Employs are trained in using best manufacturing/Assembly process. At EEssar Enoch’s Industries Pvt. Ltd.. dedicated Quality team, equipped with latest measuring equipment’s ensures that final product is delivered meeting highest quality standards to Customers.

AFTER SALES SERVICES

a) Commissioning / Assembly and installation.

b) Performance Check.

c) Maintenance & Field Services

d) Repair

e) Case Study.

f) Optimization / Retrofit.